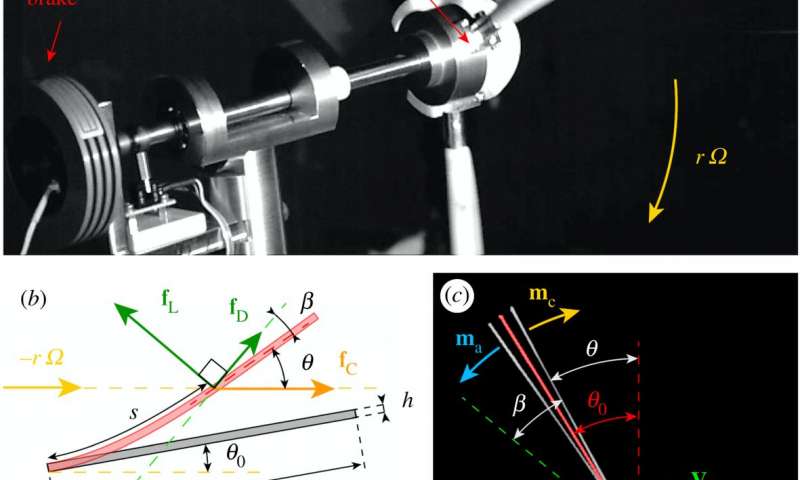

A small team of researchers with Sorbonne Université and École Nationale Supérieure des Arts et Métiers-ParisTech has found that using flexible blades on a wind turbine can dramatically increase its efficiency. In their paper published in the journal Proceedings of the Royal Society A, the team describes their approach and the results they obtained through physical testing of their idea.

After many years of research, modern wind turbines have become an effective source of alternative energy—but only under the right conditions. Big turbines used by utilities must reside in locations that offer a steady stream of the right wind speeds—too fast, and there could be damage or high maintenance costs; too slow, and the turbine blades will not turn. Now, it appears that there might be an alternative solution—using flexible blades that optimize the torque applied to the generator.

The idea for flexible blades came to the researchers after noting that most insects have flexible wings, which prior research has suggested provides creatures such as the dragonfly more power without expending more energy, by contrast with inflexible wings. That led them to create wind turbine blades that were flexible, contrary to the industry standard hard blades. After coming up with a suitable design, the researchers tested their ideas by applying them to actual wind turbines. In their tests, some of the turbines ran with the standard hard blades, some ran with very flexible blades, and some ran with blades that were approximately in the middle—not hard, but not as floppy as the other blades. They then tested each of the turbines for efficiency.

The researchers report that the hard-bladed turbines performed as expected, but the floppy blades did not work well at all—they were less efficient than the hard blades. But the middle option proved to be approximately 35 percent more efficient than the standard hard-blade turbine. They also found that the turbines worked over a wider range of wind conditions than standard turbines—they would turn under lower wind conditions and were not as susceptible to wear and tear under high wind conditions.

The researchers suggest the use of flexible blades on wind turbines offers the advantage of increased versatility and efficiency. More research is required to discover optimal flexibility and to determine if such blades are commercially viable.